Description

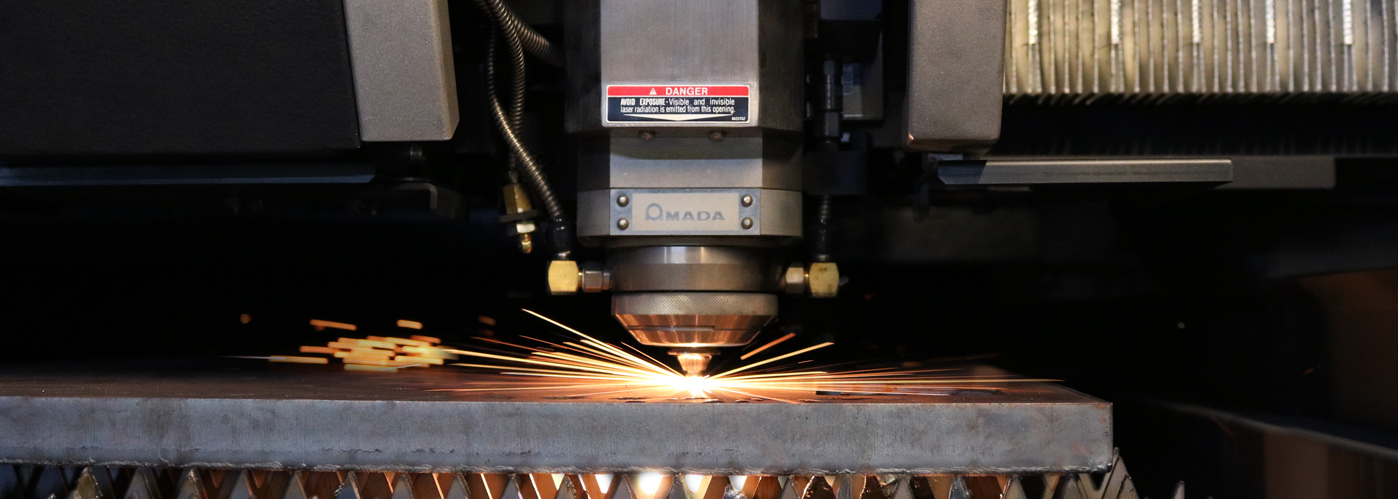

FLC AJ Series

FLC AJ Series Fiber Laser Standard Features

AMADA’s extremely productive fiber laser boasts a maximum light conversion efficiency of 75% and a maximum “wall plug” efficiency of 30%. The FLCAJ provides unmatched beam stability and quality while requiring no warm-up time. The AJ engine produces a laser beam with a wavelength that is approximately one tenth of that emitted by a conventional CO2 laser — resulting in Process Range Expansion(P.R.E.) by ensuring that unique materials such as copper (and other previously difficult to cut materials) can now be cut quickly and precisely. The benefits of fiber laser technology are:

- Faster cutting of thin material (2 to 3 times that of a comparable 4000 W CO2 laser)

- Superior speed and edge quality in material thicknesses up to 7/8″ compared to other solid-state systems

- P.R.E. (Process Range Expansion) by providing the ability to laser cut copper, brass, titanium and other materials that were previously difficult to process

- No optics or space inside the cavity of the laser source – eliminating costs associated with mirrors and downtime for alignment of optics

- The reduction of environmentally harmful emissions due to it’s solid-state technology—which does not require laser gas to generate the laser beam

- Less power is consumed than its CO2 counterpart. Since there are no optics to keep cool, a smaller, more efficient chiller further enhances cost savings

- With all three axes driven by linear drives, it boasts rapid traverse speeds of 6,680″/min. and up to 2.4 G acceleration speed for the entire work envelope

- The wear of components typically associated with ball-screw or rack and pinion systems has been eliminated

- An auto-nozzle changer automatically changes nozzles based on material cut conditions ensuring that the laser does not sit idle while waiting for an operator to setup for the next job

- The shuttle tables externalize the material setup, eliminating interference with the cutting process